20 MIN Watch

Artificial Intelligence, Cloud, Aviation, Civil

Latest

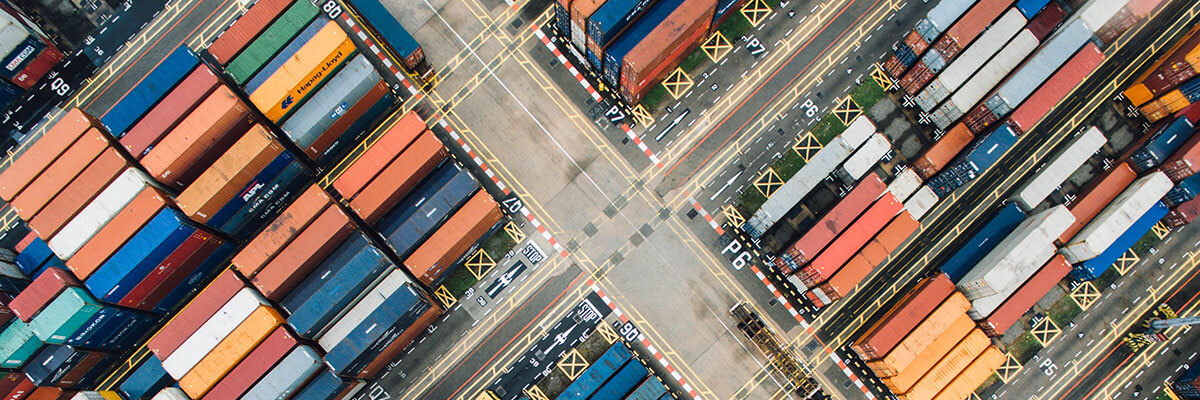

Without question, the pandemic disrupted how businesses operated for much of the last year. In many areas, this disruption has continued. In others, it’s changed the way we do things – in some cases, for the better and forever.

Collaboration and communication tools will become even more important as we enter this post-covid future, as will innovation and tools that leverage artificial intelligence and machine learning, for example. The tools are a means to better run better performing supply chains.

As a leader of a global security engineering and hybrid supply chain, I see how the best commercial practices and technology can be merged to meet stringent federal accounting, acquisition and security requirements. From my over 20 years in supply chain management, much of what COVID changed in our industry was overdue and is here to stay.

Prior to the pandemic, GDIT had well established supply chain best practices and formal training programs throughout our organization, as well as our parent company, General Dynamics. These best practices flowed down to programs and to the teams leading them on the ground.

As an example, we maintained a diverse and distributed network of distribution centers around the country. Part of this was due to the nature of the work we do across national and domestic security. We had small, need-to-know teams doing cleared work at smaller facilities, in some cases. But another reason we did this was to preserve the continuity of operations for clients.

When the pandemic hit, organizations relying on a handful of large, densely staffed distribution centers found themselves hamstrung and had to resize and rescale their operations. Now that they’ve made this pivot, investing the time and resources to do it, this model will continue into the future.

On the vendor side, GDIT has also prioritized distribution and diversity for quite some time. This approach served us well: the due diligence tools, education and alignment with our programs – which were all already in place – enabled us to work quickly and nimbly at the outset of the crisis.

As one example, we were able to secure personal protective equipment for an entire customer agency because our supply chain team was able to detect nefarious actors, because we manage the door-to-door chain of custody of goods we procure for our customers, we could ensure the secure and sustainable supply of these critical items.

Our tools, education, partnerships with customers, security of custodial control – all of this enabled us to come through for our customer and our teams in and immense time of need. Conversely, the lack of these diligence tools proved incredibly consequential for firms that did not have them. Today, those organizations are making important, renewed investments in vendor due diligence.

At the heart of any successful team are its people. And the people who made supply chains work amid the toughest of circumstances last year are going to be the ones who help build on what we changed to create even more sustainable and effective supply chains in the future.

Looking ahead at the post-pandemic supply chain landscape, we’re going to see an increased demand for flexibility and resilience. Across the board, people are going to be reluctant about returning to offices, so hiring talent to come to distribution centers will be more difficult and more competitive. Employers will have to get creative and maintain the flexibility they demonstrated throughout the last several months.

GDIT also put alternative scheduling methods into place during the pandemic. This kept the continuity of operations going, enabled us to work with appropriate safety and distancing protocols in effect, and allowed us to offer consistent and reliable work for our employees – even as others in their communities lost jobs and income.

Additionally, this flexibility enabled working parents to be home with their children during school hours as schools remained closed throughout much of the country. While supply chain work doesn’t always lend itself to remote working, this kind of flexibility enabled us to keep teams in place and offer economic security in a time of immense uncertainty.

The demand for flexibility – in whatever form is possible for the job – will continue, and we’re already seeing permanent workplace changes as a result.

Learn more about GDIT Logistics and Supply Chain.

20 MIN Watch

Artificial Intelligence, Cloud, Aviation, Civil

11 MIN Watch

Artificial Intelligence, Civil, Smart Government

42 MIN Listen

Digital Modernization, Civil

10 MIN Watch

Civil, Defense, Homeland Security, Intelligence